At Nearshore Now, we take pride in our diverse capabilities, offering a range of specialized services to meet the unique needs of our clients. From sheet metal fabrication and CNC manufacturing to sandblasting, wire forms, welding, and electrostatic paint application, our state-of-the-art facilities and experienced team ensure top-notch quality across every project.

We use modern machinery that is capable of machining all types of parts, and we specialize in assembling arrows, couplings, and flanges, as well as manufacturing locomotive parts of all kinds. In addition, we manufacture fixtures for production or assembly. Our quality department is highly trained and well equipped, allowing us to ensure the quality of our products.

We use a Coordinate Measuring Machine (CMM) to measure each piece accurately. We also use CAD-CAM technology to design and manufacture exactly what our clients require.

We currently have in use three Doosan Milling CNC machines, four Hardinge Milling CNC machines, and two Mori Seiki Lathe CNC machines.

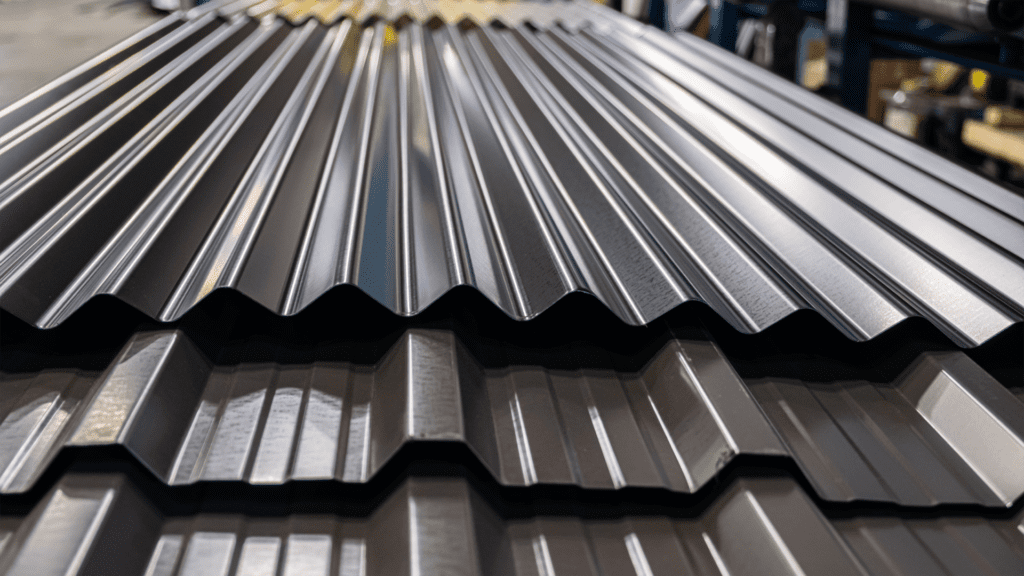

We use various types of equipment for sheet metal fabrication, including punching machines, mechanical bending machines, and a CNC hydraulic bending machine with 200 tons of pressure.

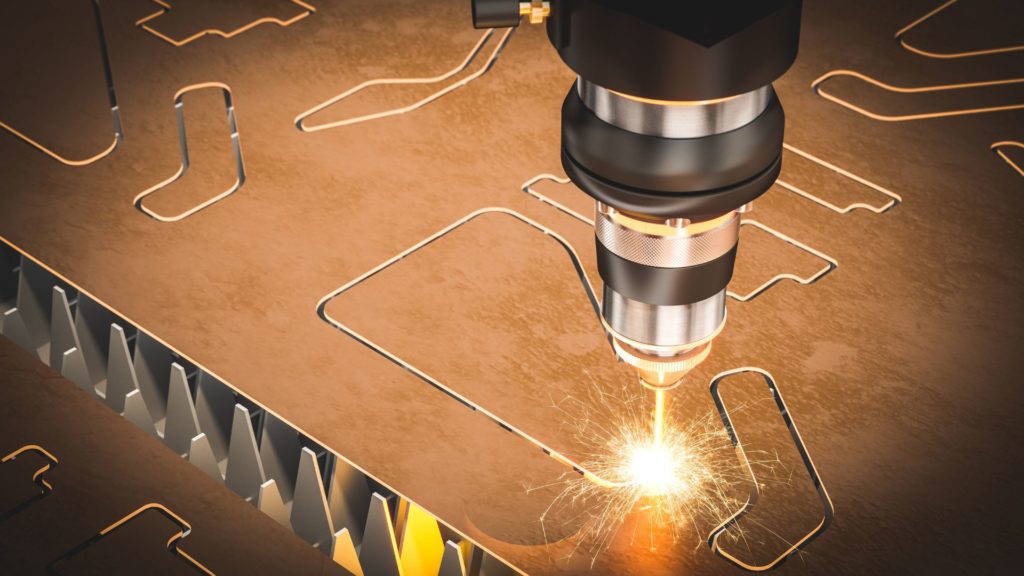

We also have a CNC laser cutting machine with Cypcut and Radan software systems. Our fiber optic laser cutting equipment is highly advanced and ideal for cutting sheet thicknesses up to 1”. It can cut a wide range of materials, including stainless and carbon steels, as well as different alloys of aluminum.

We currently have in use three Durma Bend machines, two Yawei Laser cut machines 3000w, one Bimex 1800w Laser Cut machine, and two Amada Punching machine.

The Sandblast manufacturing division specializes in sandblasting, also known as abrasive blasting. This process involves forcefully propelling a stream of abrasive material against an object’s surface to smooth rough surfaces or roughen smooth surfaces, depending on the object.

Sandblasting is frequently used as part of the finishing process to remove materials from an object’s surface in preparation for coating.

Our Wire Forms division specializes in producing custom wire guards, security cages, finger guards, fan grills, and face guards.

For over 15 years, we have been a leading manufacturer in this fi eld. We have worked with lighting manufacturers, HVAC and electrical contractors, industrial and educational facility operators, government agencies, and OEM manufacturers to design and fabricate custom wire guards tailored to meet their specific needs.

Our team is composed of experienced individuals with over 30 years of experience in the manufacturing industry. Our experts come from a wide range of industrial sectors, including heavy manufacturing, mining, steel, cement, chemical, power generation, environmental management, water distribution, water treatment, and oil and gas industries. Our team has both national and international experience.

Our employees possess a range of capabilities within these industrial fields, including manufacturing, project development, business development, quality control, and more. We validate our procedures and welders under the American Welding Society (AWS) norms to ensure high quality standards.

We currently have in use three Millermatic 252 machines, eight Miller CP 302 machines, four Lincoln Power MIG machines, two Champion Elite 253 machines and one Syncrowave 250 machine.

Stay in the know of Nearshoring and Manufacturing in Mexico industry trends and tips. Follow our LinkedIn Page where we post weekly on about what is happening at Near Shore Now and in the industry.